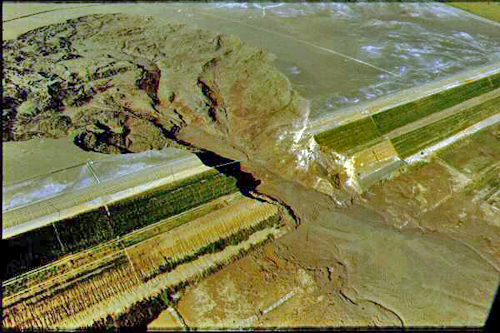

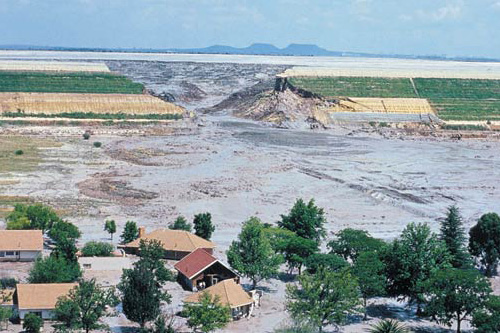

Merriespruit, 22 February 1994

On 22 February 1994, the Merriespruit No 4 tailings dam failed after a torrential downpour with an estimated 600,000m³ of water. Tailings poured over a distance of 4km engulfing 80 Merriespruit homes and claiming the lives of 17 people in the gold mining town of Virginia in South Africa’s Free State province.

The official investigation into the disaster indicated that the tailings dam did not have the mandated freeboard to cope with this rare kind of rainstorm. Freeboards are used to control water and minimise the possible uncontrolled spilling of water and/or tailings. Line management and the contractors responsible for managing the dam were held directly responsible, with heavy fines imposed.

The Merriespruit disaster led to the development of a Mandatory Code of Practice on Mine Residue Deposits for all operators of tailings dams in South Africa. This set new standards that include the management of excess water, an increase in the height of perimeter walls, qualification requirements for tailings dam management personnel and limits on how close human habitation should be allowed to encroach on tailings dams.

In the years that followed, South Africa ranked among the international mining domains that led the way in terms of tailings dam management standards. The International Council on Mining and Metals (ICMM) – whose members are the world’s leading mining companies and more than 30 national associations, including the Minerals Council South Africa – also assumed a greater leadership role in tailings management.

When tragedy struck again at Brumadinho in Brazil on 25 January 2019, where a tailings dam failure claimed 200 lives, the Minerals Council South Africa’s Board resolved that all members should review their tailing storage facilities’ construction, maintenance and operating protocols to ensure the stability and safety of these facilities for the surrounding communities.

In 2020, the ICMM published the Global Industry Standard on Tailings Management (GISTM) which strives to achieve the ultimate goal of zero harm to people and the environment. The Standard aims to prevent catastrophic tailings dam failure and enhance the safety of tailings facilities across the globe. It is directed at operators and applies to tailings facilities for both the present and future. It also indicates how extreme the consequences can be towards the environment and communities in the case of a tailings facility failure.

The GISTM comprises six key points:

- Project-affected people must be afforded opportunities for meaningful engagement in decisions that affect them throughout the tailings facilities’ lifecycle.

- Operators must develop knowledge about the social, environmental and local economic context of a proposed or existing tailings facility.

- The ongoing use of an updated knowledge base, consideration of alternative tailings technologies, the use of robust designs and well-managed construction and operation processes must be used by operators to demonstrate the ability to upgrade a facility at a later stage.

- The designation and assignment of responsibility to key roles in tailings facility management must focus on the ongoing management and governance of a tailings facility..

- There must be a focus on emergency preparedness and responses in the event of a tailings facility failure where operators plan ahead, build capacity and work collaboratively with other parties, in particular, communities.

- Operators must commit to transparency and participate in global initiatives to create standardised, independent, industry-wide and publicly accessible information about tailings facilities.

As of 5 August 2020, all ICMM members committed to implement the GISTM. The Minerals Council South Africa supports the GISTM and calls on all its members to study the Standard and to work towards ensuring that their tailings management systems are in line with those contained in the Standard. All tailings facilities operated by members with 'extreme' or 'very high' potential consequences were committed to be in conformance with the Standard by 5 August 2023. All other tailings facilities operated by members not in a state of safe closure are to be in conformance with the Standard by 5 August 2025.

As the mining industry remembers and mourns the lives of those people whose lives were cut short on that evening of 1994 in Merriespruit, we recommit ourselves to ensuring that mining is safe for our country’s mineworkers, their families and the surrounding communities.

![Logo MCSA [logo]](/templates/chamber/images/logo.svg)